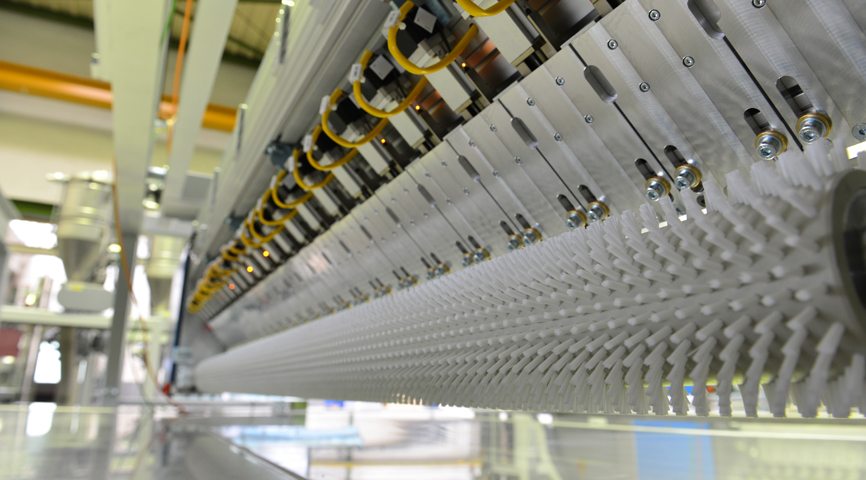

Granule scattering machine with rotary brush system

Versatile scattering unit with a rotating brush system for uniform scattering of bulk granules.

Typical applications for this IPCO precision scattering unit include:

- Granules for homogeneous/heterogeneous flooring

- Granules from plastics or composites for the construction, furniture and automotive industries

- Decorative surface effect coating

- Recycling material

Feeding of the powder to the funnel-shaped charging hopper is carried out by means of suction or screw conveyors. Inside the charging hopper the bulk material is uniformly distributed and the level is kept constant during the scattering process.

The formation of cavities and decomposition of the material is avoided through the use of a special mixer. The scattering roller is mounted below the hopper and is designed according to the grain size of the bulk material.

The granules are picked up by the scattering roller and stripped at a rigid doctor blade that is split up in adjustable segments. After that the accurately dosed granules are conveyed to a rotating brushing device.

Features

- Doctor blade with adjustable segments (manual or electrical)

- Scattering rolls with cells designed to suit sizes of granules

- Clockwise and counterclockwise rotation of the brush-off roller

- Easy adjustment of the distance between brush and scattering roller with position display

- Shell clamping device enables easy change of brush roller – distance to scattering roller remains unchanged

- A supplementary set enables this system to be changed to an oscillating system for scattering of powders

- Standard scattering widths from 400 – 4,200 mm